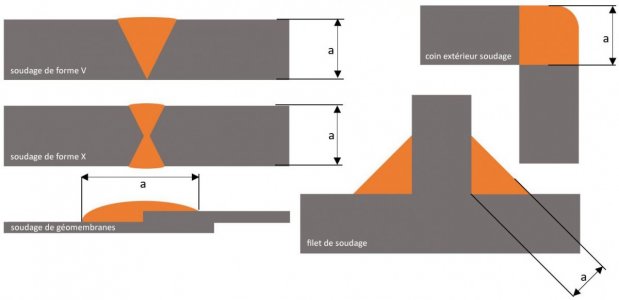

Different types of plastic welding.

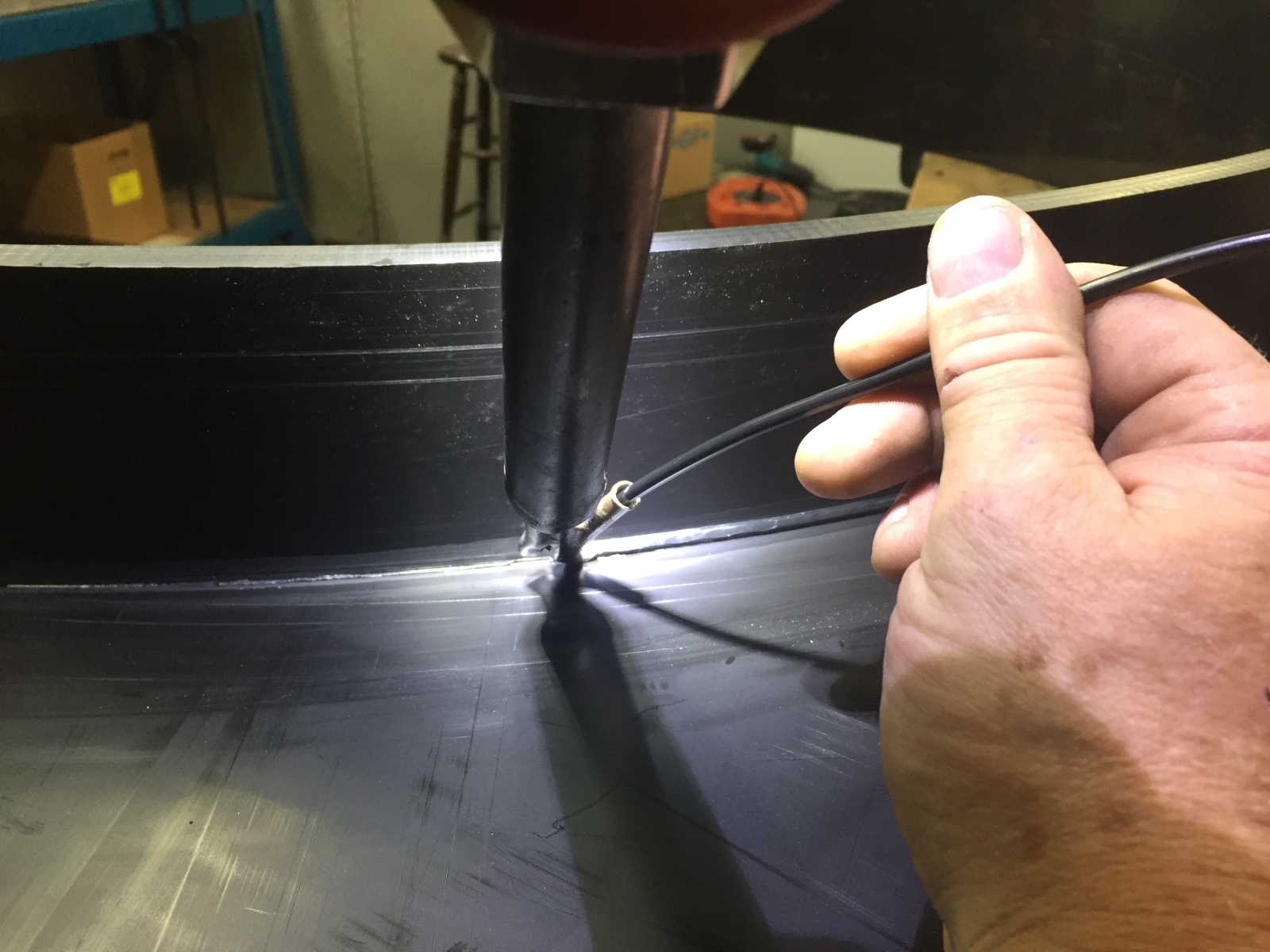

The high-speed weld is the most common. It’s made by a thermoplastic hot gas (air) welding torch and rod. We apply many layers to assure a good contact. We use it to install connections, execute minor reparations or for work in tight areas.

The extrusion weld is similar to metal extrusion. The melted plastic rod is pushed through the nozzle to weld pieces together. We use it to install connections and to assemble some pieces of tank.

The butt weld is made without material addition. Both sheets are heated by a heating plate than pressed together. The heating temperature, the heating time, the contact pressure, the contact time and the rest time are set by the fusion equipment microprocessor and is in function of the polymer type. We use it to fusion sheets together.